In our webinars, our experts from SCHULER Consulting provide you with sound basic knowledge. You get insights into interesting applications and projects that have already been completed.

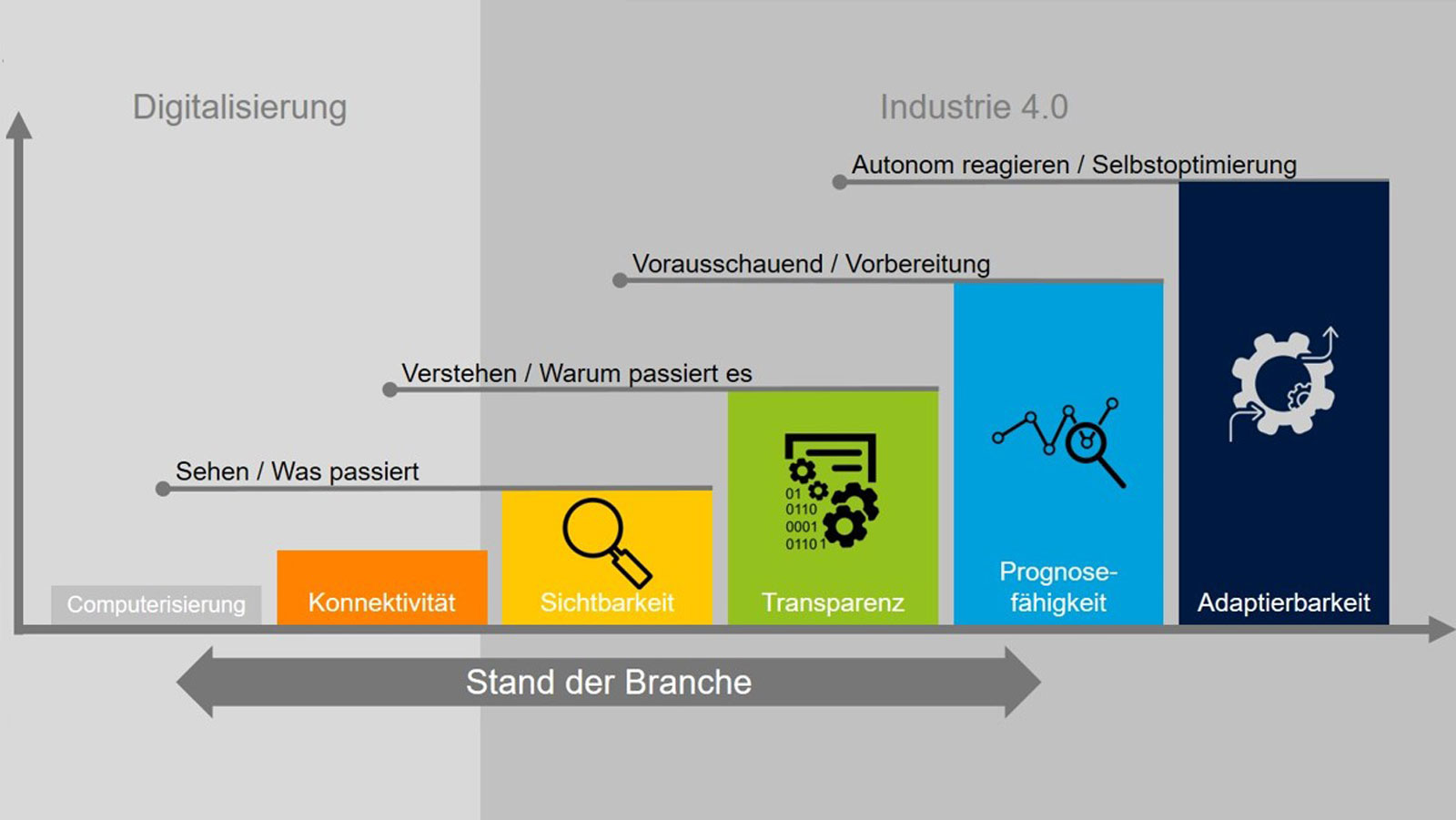

Lean 4.0

Optimization and simplification of production processes and procedures

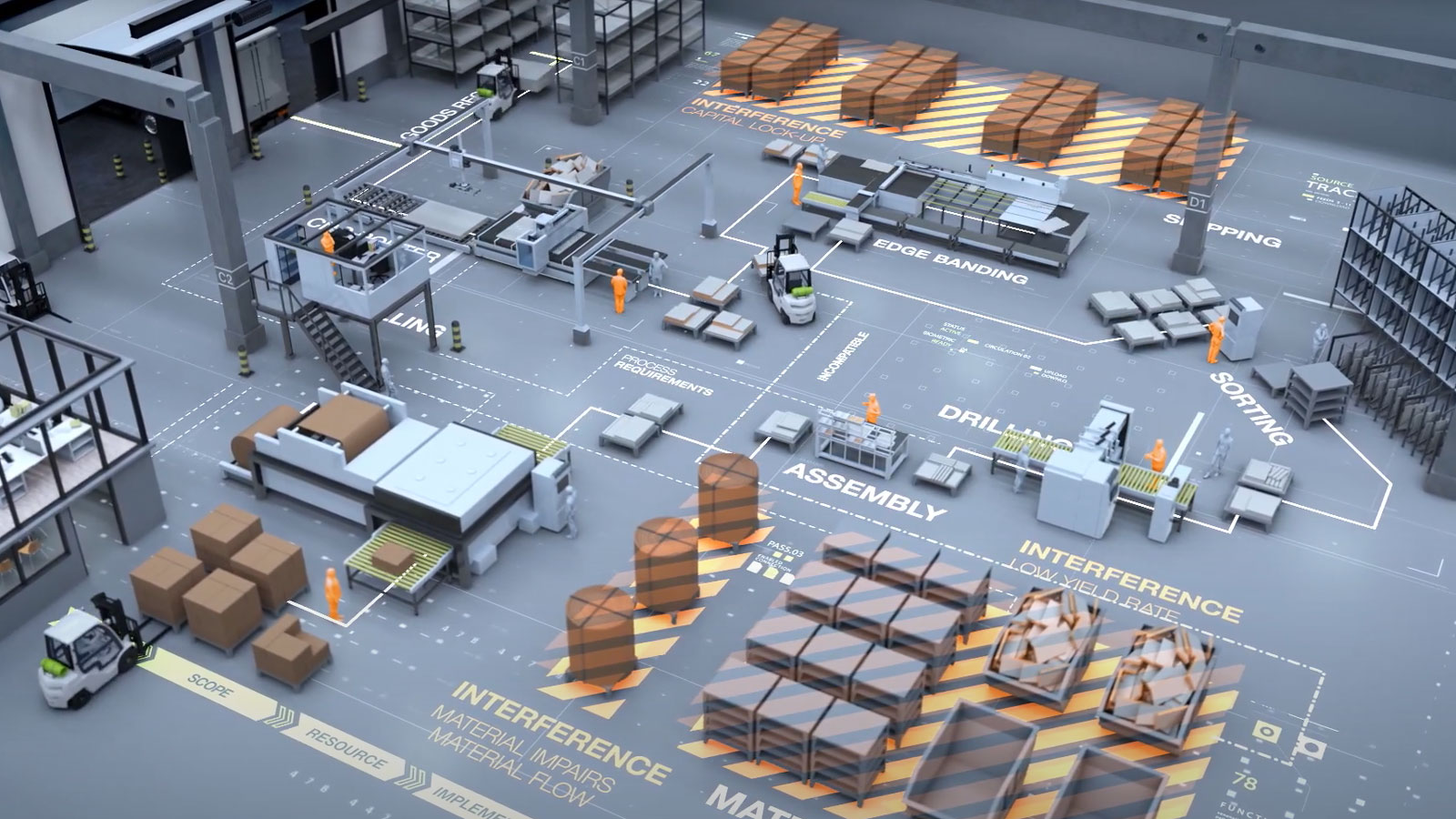

You all know it! Complex projects for the digitization of individual processes or complete process landscapes. There are enough examples of resource-consuming and lengthy implementations in the digital mapping of business processes. Perhaps you too think that this should be easier. In this webinar SCHULER Consulting will present you new approaches to simplified process digitization for a wide range of business areas. The benefits, challenges and approaches of process digitization will be highlighted. SCHULER Consulting will show you innovative ways to digitally map and continuously optimize your manufacturing processes in a resource-saving manner - day after day.

- Demonstration of possibilities for simplified process digitization

- Example applications from the practice

- Identification of numerous digital optimization potentials

- Diverse application examples for different company sizes and manufacturing philosophies

- Possible solutions / new approaches for deadlocked IT projects

Duration: 1 hour

Process optimization

Systematic optimization of production processes

In recent years, the continuous improvement of production processes has become a constant companion for successful companies. Those who do not constantly adapt processes to new customer and market requirements and develop further, lose track. On the other hand, it is also important to profit from innovations that help the company to achieve leaps and bounds in productivity and flexibility. Perhaps you have the feeling that you are just losing the connection or want to build up more pressure to innovate in your company again, we can support you in this. We combine a sustainable continuous improvement process based on lean thinking with innovative technology. In this webinar we will provide you with the basics of the well-proven approach to optimization as well as a sustainable innovative approach to continuous improvement and tracking of the optimization. Optimizations in all areas become measurable and can be applied in a more specific way.

- Comprehensive basic knowledge of the approach to process optimization

- Theoretical and practical applications

- Prerequisites for sustainable continuous improvement

- Innovative solutions for production transparency and controlling

- 100% production transparency in your company without large software investments

- Optimization projects are defined and executed based on key figures and the results are controlled

- Connection between Smart-Factory and Lean-Thinking

Duration: 1 hour