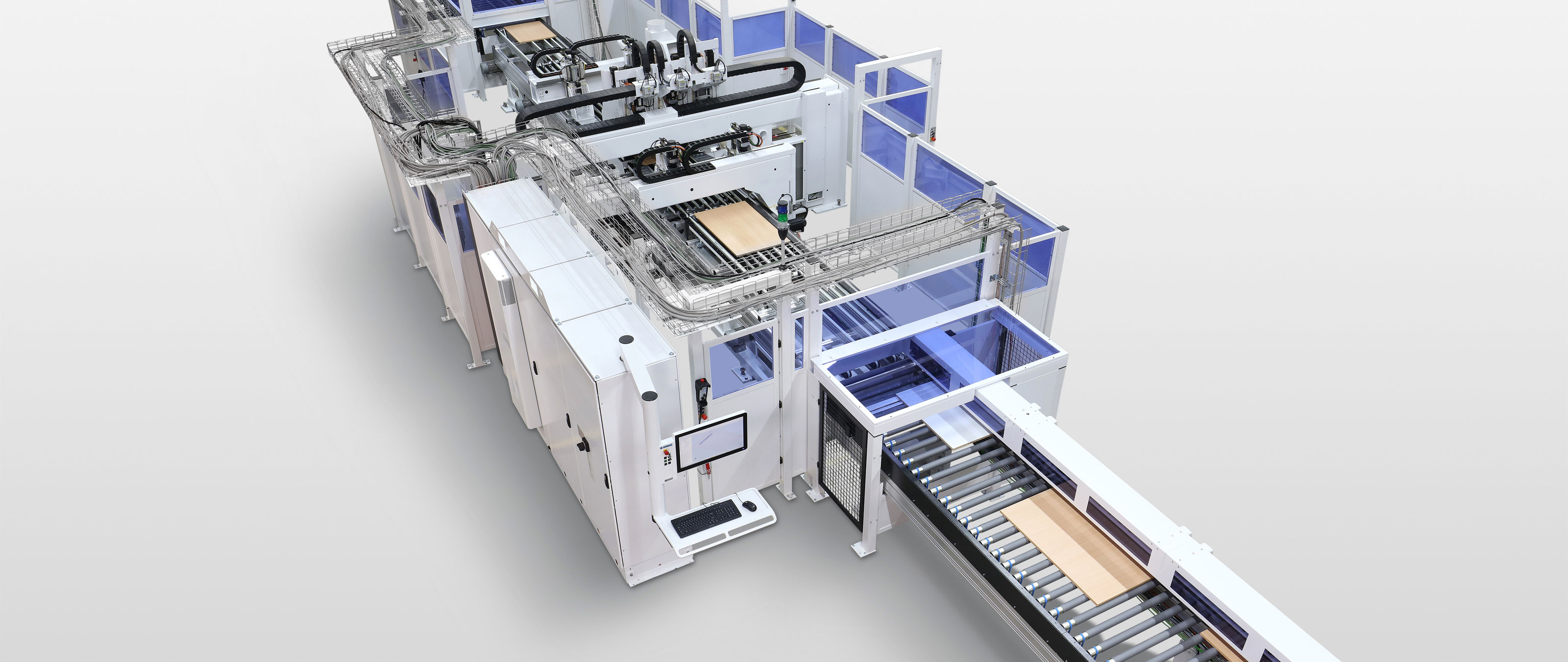

CNC Automatic Drilling and Fitting Machines DRILLTEQ L-500

CNC Automatic Drilling and Fitting Machines DRILLTEQ L-500

6-sided processing without compromises

The 6-sided workpiece processing in just one cycle offers everything the customer’s heart desires. Regardless whether drilling, routing, grooving or fitting insertion – the DRILLTEQ L-500 can combine everything individually. The integrated dynamic clamping system generally ensures safe and precise workpiece handling. As standard, all drilling units are equipped with the patented spindle clamping thus ensuring a continuously exact drilling depth.

Benefits

- 6-sided workpiece processing – complete processing in one cycle

- Safe and precise workpiece transport by dynamic clamping system

- Extremely adaptable by freely configurable equipments

- Flexible process integration as production cell or in complete production lines (batch size 1)

Images

Features

-

Aggregate for glueing and dowelling

Precise, horizontal dowel insertion with glue flow control

-

High-speed drilling block | vertical

Single-head or split-head arrangement possible. Extendable by grooving saws and horizontal drilling spindles (longitudinal edges)

-

8-fold tool changer

Quick tool changing from top and/or bottom

-

High-speed drilling block | horizontal (cross edges)

Individually activated spindles

-

Insertion aggregate for mounting plates

Alternatively mounting plates can be screwed

-

Workpiece handling

The clamping system allows safe and precise positioning of workpieces and 6-sided processing – even in edge zone

-

Routing aggregate (left/right hand rotation)

Routing of roller shutter grooves or similar and corner notching

Technical Data

| DRILLTEQ L-500 | Min. | Max. |

|---|---|---|

| Workpiece length [mm] | 250 | 2500 |

| Workpiece width [mm] | 100 | 800 |

| Workpiece thickness [mm] | 12 | 60 |

Further dimensions on request.

Technical information is subject to change.

(Previous product name: Throughfeed Processing Center ABH 100)

Brochures