Who hasn’t been in this situation: One day, the edge banding tape runs out. On the other day, too much is ordered. No one seems to have a proper overview. The solution: The Edge Data Package – consisting of the Edge Data Plugin and Edgeband Management Set. With this solution, you have direct access to all edge banding data from leading providers, right at the machine. The traditional joinery company Lechner from Upper Bavaria in Germany already uses this combination on their EDGETEQ S-500 edge bander and is thrilled.

Tradition meets modernity

The joinery Lechner, based in Forstern, is a family business with six employees and specializes in the production of high-quality furniture and objects. They work as suppliers for companies of all sizes as well as for architects, planning offices or private customers. They support the customer from the first consultation, through planning to the finished implementation of the project. The traditional joinery not only stands for first-class quality, but also relies on state-of-the-art machines and digital products from HOMAG.

Managing Director Anton Lechner acquired his first HOMAG machine in 2000 and is therefore a long-standing customer and business partner. The demand of the customers of the joinery Lechner are diverse and individual. No order is the same as the next. The joinery builds individual and customer-specific orders and can rely on its extensive machine park for implementation.

In addition to the classic joinery machines, production is also supported by four HOMAG machines. An edge banding machine EDGETEQ S-500, a CNC machining center BOF 211 (today comparable to CENTATEQ P-210) and a panel dividing saw HPP300/43 (today comparable to SAWTEQ B-300) and a sanding machine SWT535.

Short digital paths - more efficiency at the edge.

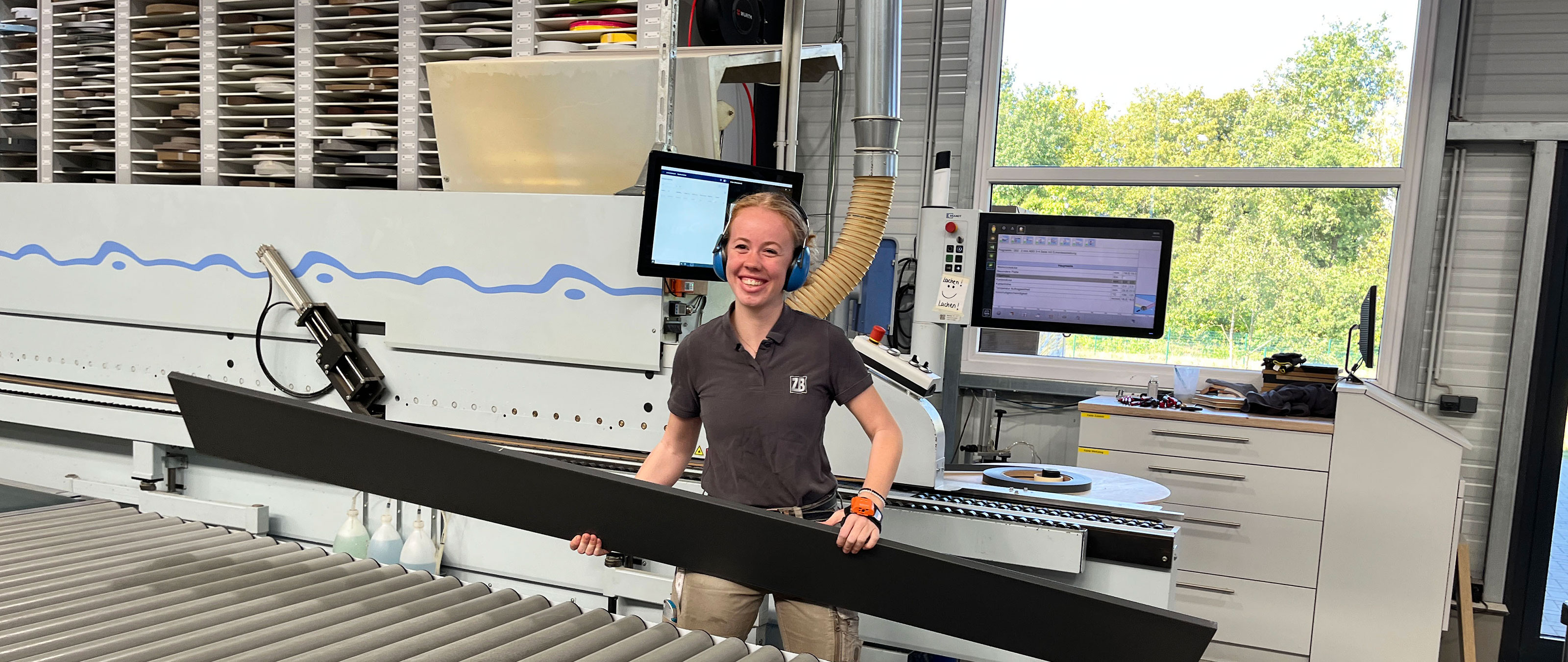

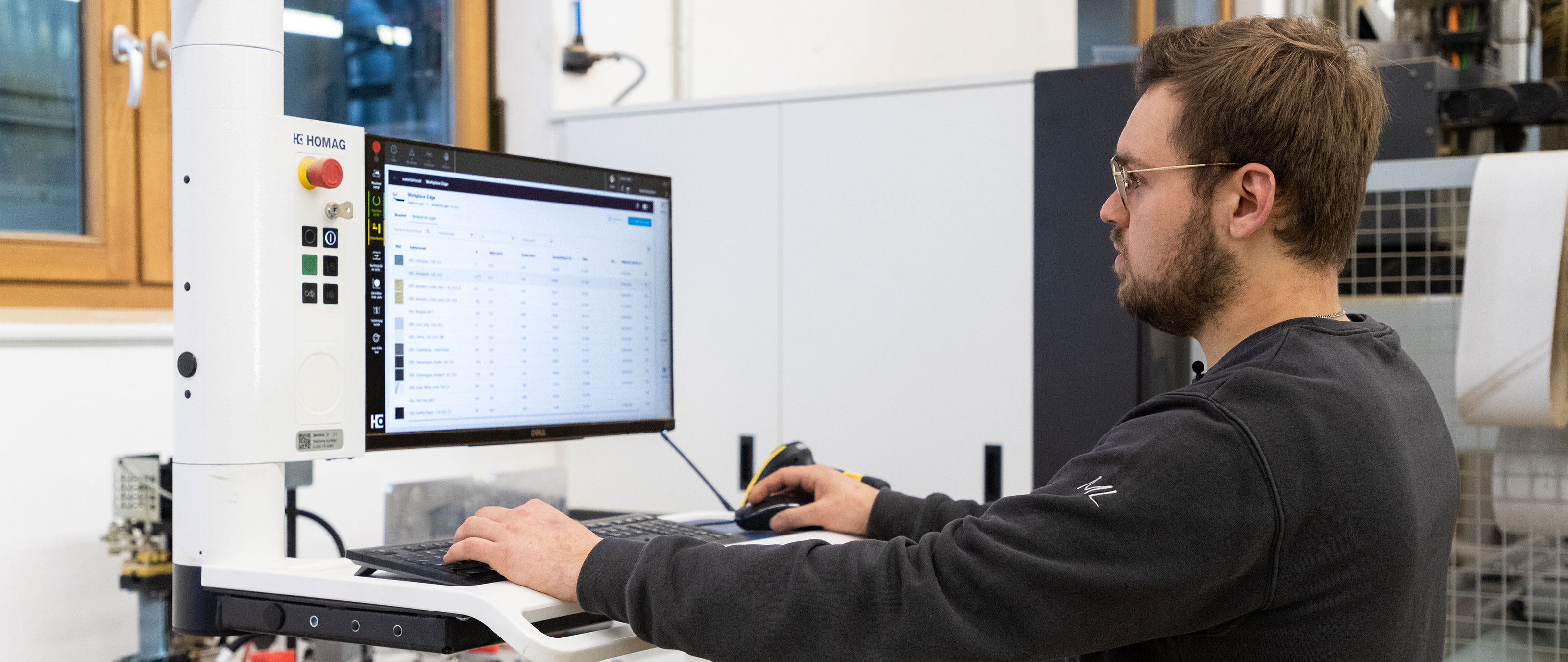

With the machine software woodCommander5, Martin Lechner selects processing programs and edge materials. Capturing production parameters and creating machine programs optimized for the workpiece is faster than ever. Thanks to 3D workpiece simulations and checking for permissible parameter combinations, the master carpenter can make the right settings in no time. Once saved, he can retrieve the basic settings at any time and thus speed up the machining process.

Equally practical in everyday life is the individually adaptable user interface, the fast orientation, and the simple handling with just a few clicks. The result: all employees can operate the software - and they do. "We don't have any employees who only perform special steps. Everyone does everything with us," says junior boss Martin Lechner. But the great strength of woodCommander5 in conjunction with the Edge Data Package lies in internal and external data exchange: through the direct connection between machine and Edgeband Management Set, which manages the edge banding material, the operator always has the current stocks in view."HOMAG is by far the most innovative."

This saves the joinery a lot of time and effort. The relevant production data such as thickness, height, and available lengths of the selected edge banding roll are transferred from the app to the machine by the plugin and automatically reports the remaining length of the used edge banding roll back to the Edgeband Management Set app through the plugin.

Equipped for the future.

The Lechner joinery from Forstern is perfectly equipped for its path into the future. The second generation is already in the starting blocks, the expansion of the machinery is being pushed forward and the dominant topic of our time – working energy-efficiently, resource-saving and networked – is firmly in focus. In the future the joinery aims to expand its networking capabilities through the digital tool management system twinio from tapio.

“We can access all material and edge banding data at any time, capture data without manual intermediate steps and, most importantly,

we no longer have multiple orders.”Martin Lechner, Master Carpenter, Lechner Joinery