Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

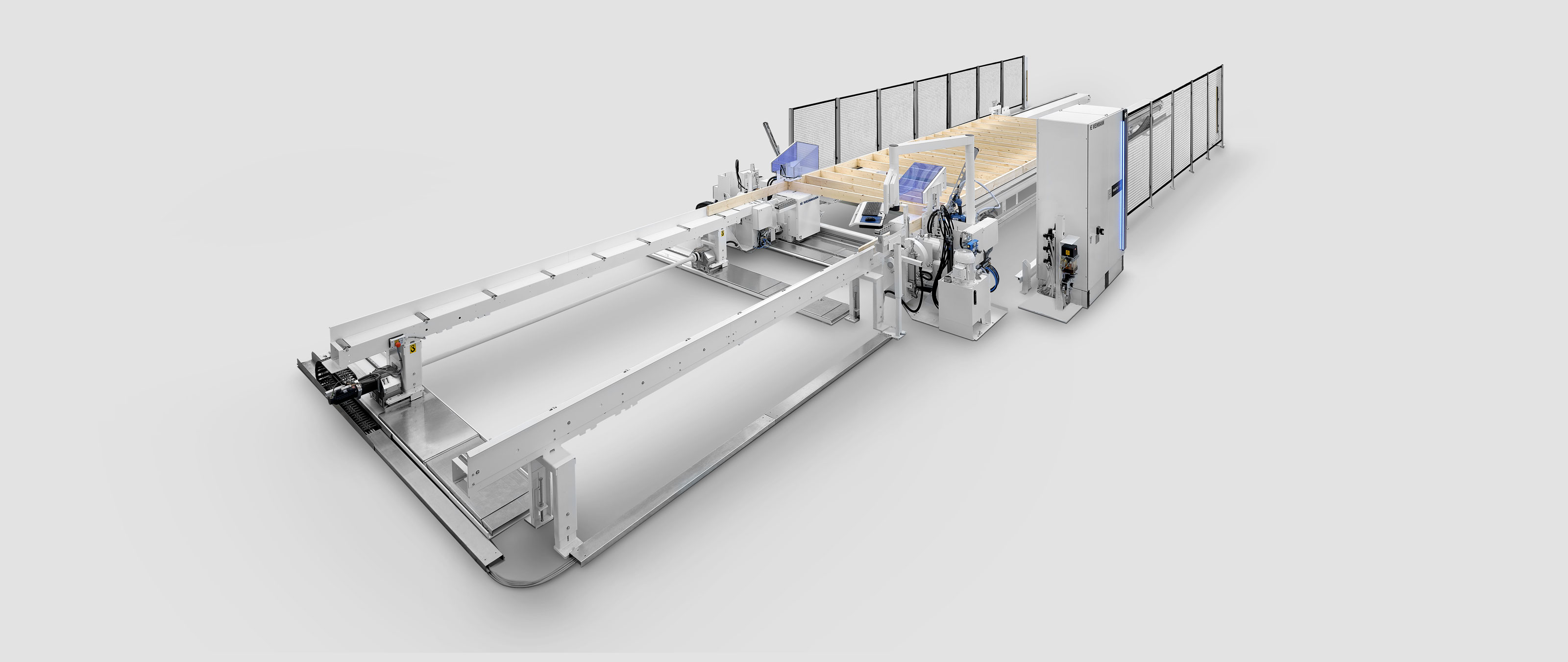

WEINMANN Framing Station FRAMETEQ F-500

WEINMANN Framing Station FRAMETEQ F-500

Complex frame works produced with ease

Complex and challenging frame works can be manufactured quickly and easily with the WEINMANN FRAMETEQ F-500 frame work station. Top and bottom plates are fed in manually, positioned at the stops and automatically tensioned. The studs are also automatically positioned, tensioned and secured. The higher level of automation offered in comparison to the FRAMETEQ F-300 significantly increases the performance of the machine.

Highlights

Further automation solutions such as automatic outfeed of elements and automatic width adjustment of the machine minimize the setup time.

Simple and automatic positioning, clamping and fastening of the studs and belts inserted enable efficient production.

The versatile configuration options enable the frame work station to be adapted to the customer's needs.

Images

Technical Data

| Wall thickness [mm] | 75 - 200 Optional: 300 |

| Wall height [m] | 1,5 - 3,2 Optional: 3,8 |

| Wall length [m] | 6/ 8/ 10/ 12 |

| Production capacity [mm / min] | 800 - 1,500 |

(Previous product name: Frame Work Station WEM 150)

Here's how your colleagues produce

Videos

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

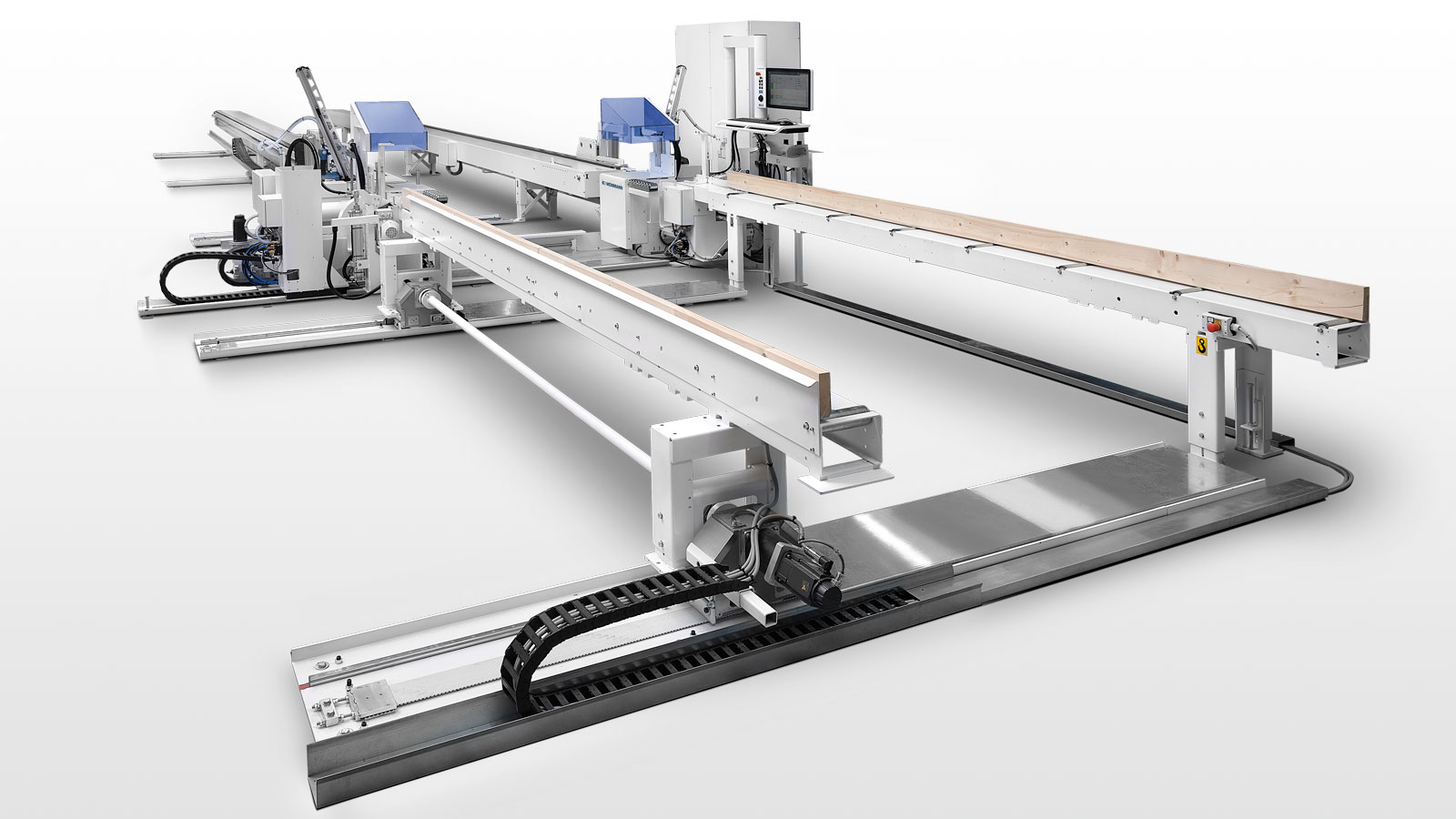

FRAMETEQ F-500 with feeding portal STORETEQ H-100

Production of a frame work with FRAMETEQ F-500 and feeding portal STORETEQ H-100.

Brochures