Theodor Schönefeldt GmbH has acquired a new system for its panel cutting process. The production specialist is taking advantage of the unprecedented combination of fully automatic and manual cutting on the brand-new HOMAG SAWTEQ B-300 flexTec pressure beam saw. This increases output and inspires flexibility.

The company Theodor Schönefeldt GmbH – Büro- und Objektmöbel was founded in 1991 from part of the former furniture combine Zeulenroda in Neustadt/Orla, in Germany. In 1997, Andreas Balnuweit (an industrial clerk) and Andreas Watzinger (a carpenter and wood engineering graduate) took over the business from its founder Theodor Schönefeldt. The company's range of services includes the design, manufacture and installation of custom furnishings, with a focus on nursing homes, homes for the disabled and student residences, daycare facilities and hospitals. The company works primarily with large furnishers.

Setting the course for the future with new construction

Around ten years ago, the manufacturing specialist built a new production hall (4000 m²), as well as a new office building. As part of the new construction, almost all of the machines were replaced with new ones. This included a saw-storage combination, two edge banding machines, and a CNC processing center. Andreas Watzinger and Andreas Balnuweit invested in the expertise and the machine technology of their long-term technology partner, HOMAG.

The company has a team of 40 employees, with around two thirds of them working in production — almost all of these are skilled workers. The company also trains wood technicians. However, the lack of new blood and skilled workers is also a big issue here. Andreas Watzinger: "We have one apprentice per year. We would like to train a lot more, but it is extremely difficult to motivate young people to undertake an apprenticeship."

Challenges for data and information flow

In terms of software, the company currently uses Imos (CAD) and OSD (industry software). Watzinger: "There is a trend toward office and work preparation. While I am not sure whether this is a good thing or not, I do know that integrated, fault-free processes in production require absolutely faultless work preparation and organization. The performance is entirely reliant on the quality of the data and information flow. This is an ongoing challenge."

Investment in a new panel dividing concept

Theodor Schönefeldt GmbH processes a wide range of decors and different materials. HPL is also cut to size in Neustadt and pressed onto carrier plates. This poses significant challenges in terms of planning, production and internal company logistics — particularly for panel cutting. Hence, the two bosses were excited when they learned of a new development from their technology partner HOMAG: the SAWTEQ B-300 flexTec panel dividing saw, which enables both fully automatic and manual operation. A world's first. Watzinger and Balnuweit chose to invest in this machine as a pilot customer. The machine was commissioned in July. At the same time, the software of the existing automatic panel storage system was upgraded to the latest version.

Interesting features on board

The saw blade projection is 95 mm (which is important for cutting packages). The cutting of different materials is supported by, for example, slide rails for thin panels, a cutting gap closer, or the ability to define material-specific parameters in the CADmatic 5.0 control system for the respectively correct clamp pressure and pressure beam pressure. The saw is, of course, also tapio-ready.

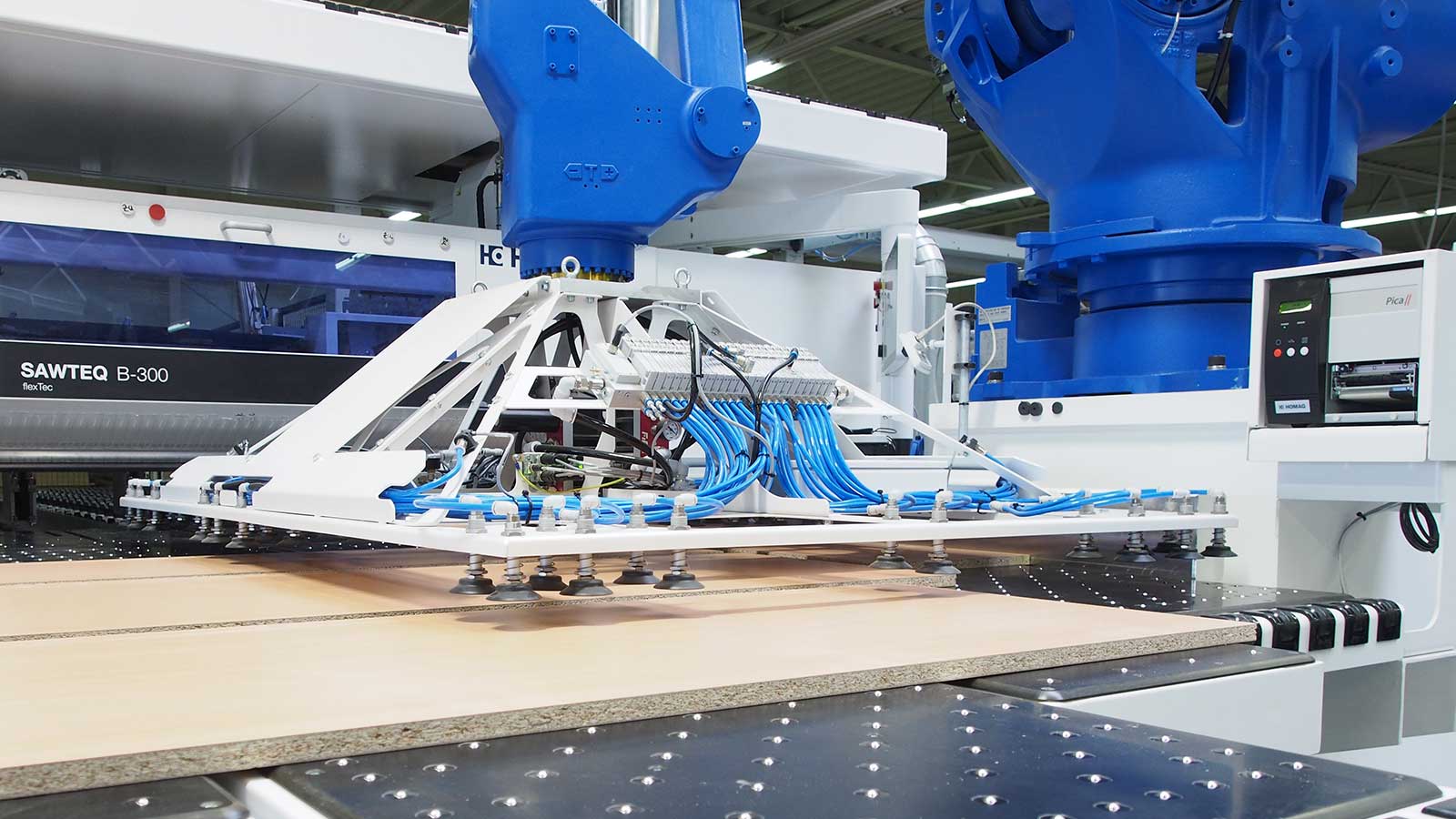

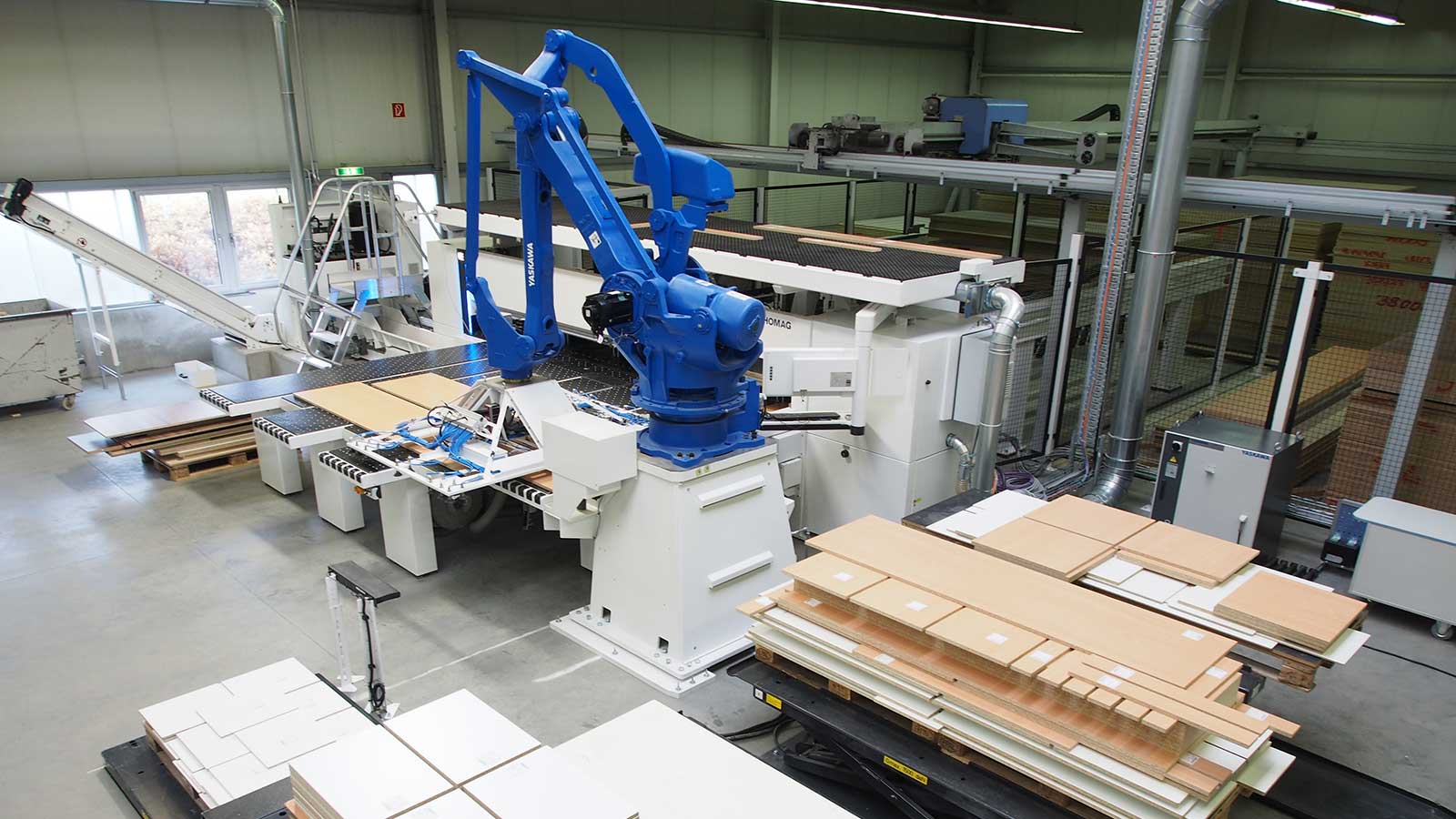

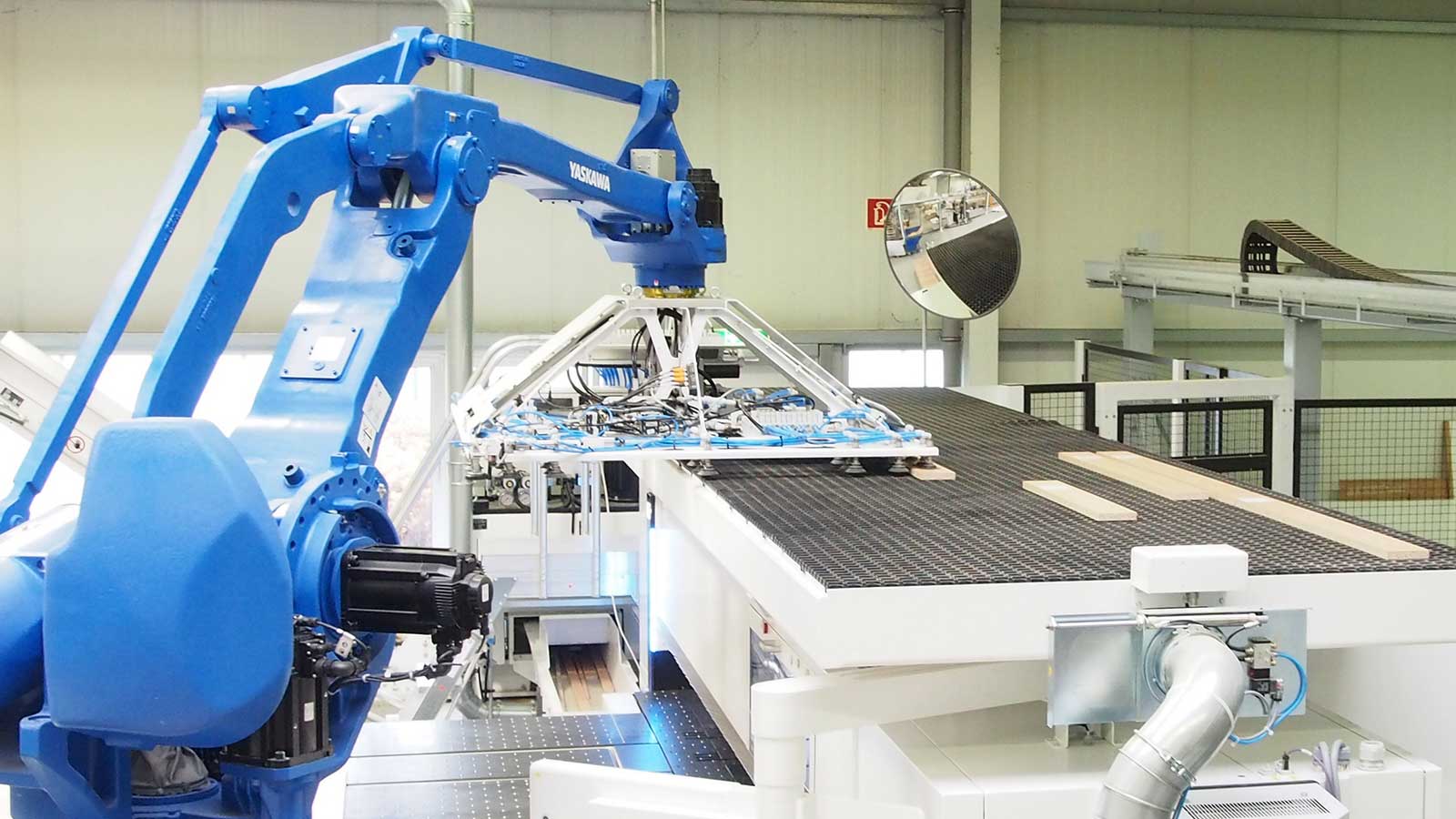

Spectacular automatic operation

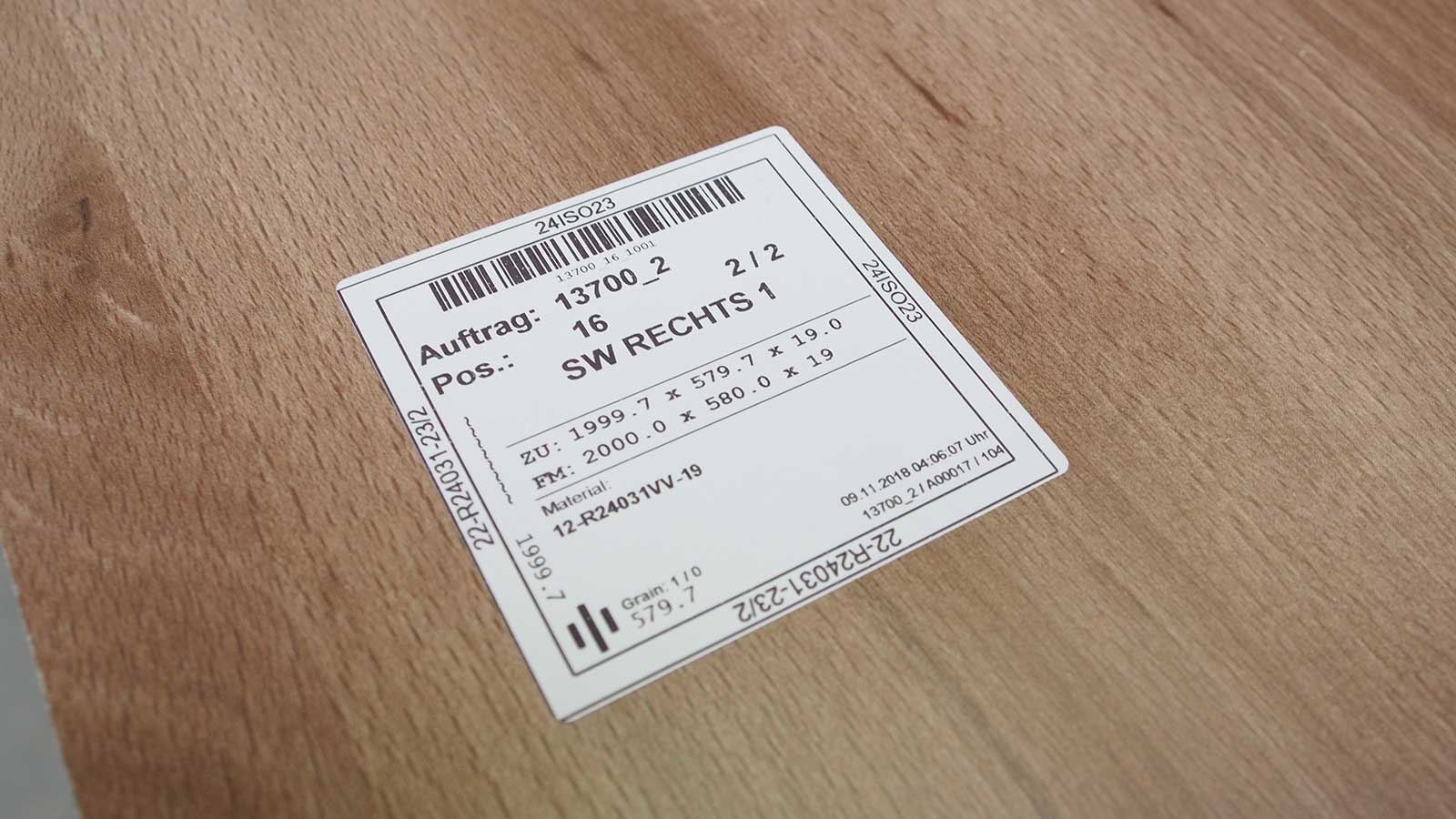

During unmanned automatic operation, a robot with a suction rail takes over the entire material handling during the sawing process, after the material has been fed to the saw from the automatic panel storage system. It's spectacular to see how the robot independently places the parts in intermediate storage, turns them, and at the end, places them automatically on one of the five destacking stations. The level of "intelligence" that the HOMAG specialists have given the system is remarkable. Labeling is of course also fully automatic. The labeler is located near the pressure beam.

Cutting to size manually and flexibly

Not all of the tasks performed at Schönefeldt can be carried out automatically. Examples of this are the splitting of HPL and package cutting. Here, the concept offers the unique advantage of enabling both automatic and manual operation.

The lanes between the air cushion tables are each equipped with two folding tables. In operator mode, the tables can be folded up or down to enable easy access to the cutting line or to prevent thin materials from sagging and to increase the work area. In manual mode, depending on the cutting task, labeling also takes place fully automatically or manually via an additional printer installed on the front of the saw.

Quickly up to speed

Andreas Watzinger is happy with the machine just a few months after commissioning: "We use the machine in a three-shift operation. Currently, two of these shifts are carried out manually. The aim is to achieve two shifts of automatic operation. With an average of 800 parts per shift, we have already doubled our capacity compared to the previous plant."

Employees involved at an early stage

The employees affected were involved in the investment in the SAWTEQ B-300 flexTec from an early stage. Andreas Watzinger is proud of his team: "Our employees have shown a lot of commitment and played a constructive role. They have contributed significantly to the entire workflow running smoothly. In constant dialog with the HOMAG experts, together we have been able to quickly tailor the concept optimally to our needs."

“We use the machine in a three-shift operation. Currently, two of these shifts are carried out manually. The aim is to achieve two shifts of automatic operation. With an average of 800 parts per shift, we have already doubled our capacity compared to the previous plant.”Andreas Watzinger, Managing Director Theodor Schönefeldt GmbH

More about Theodor Schönefeldt GmbH

The company Theodor Schönefeldt GmbH – Büro- und Objektmöbel was founded in 1991 from part of the former furniture combine Zeulenroda in Neustadt/Orla, in Germany. The company's range of services includes the design, manufacture and installation of custom furnishings, with a focus on nursing homes, homes for the disabled and student residences, daycare facilities and hospitals.