An article from the trade magazine BM, 05/2024. Images: BM / Christian Närdemann

The joinery in Augsburg is mainly involved in the field of furniture and interior fittings. Raimund Issle (45) took over the company from Hubert Sannwald more than 2 years ago and currently employs 11 people, including a trainee. The portfolio of the production specialist covers all areas of furniture and interior fittings for private and commercial customers.

Digital right from the start

Raimund Issle likes things "digital right from the start." His aim is to transform the traditional joinery into a modern, digitalized workshop. He is a great fan of consistency — which for him, by the way, starts with the digital 3D dimension. One of his first projects was to bring the machine pool and various work areas online. To do this, around 8 km of cables and data lines were laid in the workshop and office. For example, the horizontal panel saw and the two CNC processing centers from HOMAG are directly connected to the company network.

Panel cutting significantly optimized

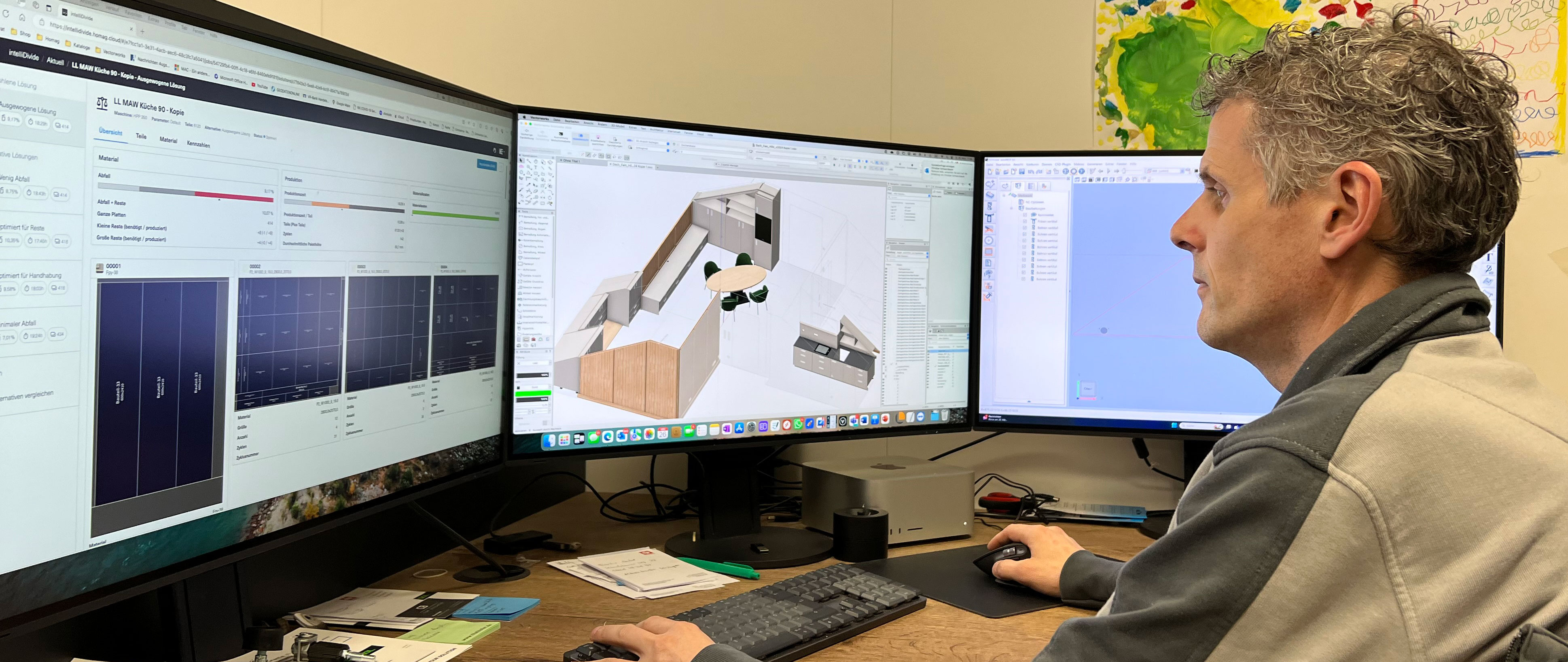

Issle maintains a technology partnership based on trust with the HOMAG Group. With powerful optimization software and various digital assistants from the world market leader in the Black Forest, in recent years he has significantly improved the productivity of the existing machine pool. In 2022, Issle first introduced the web-based optimization software intelliDivide. Up until then, hand-written parts lists were entered directly into the computer of the panel dividing saw (year of manufacture 2011) in the joinery, and the cutting pattern was generated locally on this computer.

Raimund Issle is pleased that as far as he is concerned, the use of the optimization software and its various options has not only increased the performance of panel cutting by more than 30%; "We can now also process large jobs that would otherwise not be feasible. In addition, there are significantly fewer errors and much less waste. The slight increase in time required for work preparation is worth it."

The workflow in intelliDivide is simple: after uploading the parts list (e.g. from the industry software or CAD), the user can start the optimization immediately. What's special about intelliDivide is that it calculates different solutions and presents the alternatives clearly in a graphic. Depending on the range of parts, mix of materials and the job size, a whole series of different optimization options are possible: e.g. fewer offcuts, minimal handling, minimal material costs or the shortest processing time. The user decides for themselves which cutting pattern is the right one. The clear presentation of the results makes it possible to record the most important key figures, such as material consumption and costs or production times at a glance.

After optimization, the cutting patterns are available directly in the network for processing on the panel dividing saw. intelliDivide offers an interesting new function with "templates." During optimization, this new function enables the user to keep parts together that are arranged next to each other on a front, for example, and for which a continuous veneer pattern is important. These are cut first as one workpiece and then separated later. As intelliDivide is a web-based software, there are no maintenance or update costs. The software is always up to date. All employees use a joint company license.

Efficient material management

This year, Raimund Issle and his team have introduced two additional tools: cloud-based offcuts and panel management as well as cloud-based edge management. These tools will be used to significantly simplify and speed up processes even further. The materialManager is the basis for the two digital assistants. It provides a permanent overview of all materials and stocks of edgebands and panels as well as their storage locations including offcuts and allocations.

Edge handling made easy

The optimization effects are particularly evident in the area of edge handling. The edgeband assistant provides all the information about the edge material, its stock and storage locations. In addition to the materialManager and materialAssist apps (edgeband management on the rack), the scope of delivery includes a label printer, the HOMAG Cube (control box for connecting the rack and the printer to the Internet and the apps), downloadable construction plans and optional LED strips for the edge rack.

This is how it works: once the edge material and all its data have been created in materialManager, it can be managed centrally there. The app shows the latest stock levels and the precise locations of each roll at any given time. In production, the edge rolls are stored in the edge rack and all information is stored in the materialAssist app on the tablet. All information about each edgeband (properties, offcut length) can then be called up easily. The labels for identifying the edgebands can also be printed just as easily. If a workpiece now requires edging, the user simply selects the correct edgeband in the app or scans the corresponding code on the job slip. The storage location is then indicated by illuminated LEDs on the edge rack.

Searching for the correct edge material is therefore a thing of the past. Raimund Issle comments with a smile: "From chaos we created an overview." After edging, the offcut length of the respective roll is updated in the materialAssist app with a few simple entries on the tablet. The update is then also performed automatically in materialManager.

Processes are much more transparent

Raimund Issle is pleased: "With the software tools from HOMAG, we have been able to significantly increase the productivity of our existing machines. In addition, the processes are much more transparent." What is also remarkable is that in production, the joinery is already almost paperless. Issle is already planning further optimization stages. He is currently introducing productionManager in the company — the digital job folder from HOMAG. This gives all employees real-time access to all information about every job — from the foreman's office through production and to the assembly area.

However, the web app doesn't just effectively support the end-to-end organization of data: it also makes the current processing status of all components transparent in production. Issle sees his joinery on the right track to further optimize productivity with the digital tools and thus strengthen its competitiveness in the long-term.

“We can now also process large jobs that would otherwise not be feasible. In addition, there are significantly fewer errors and much less waste. The time required for work preparation is slightly higher, but it’s worth it.”Raimund Issle, Managing Director of Issle und Sannwald GmbH carpentry workshop