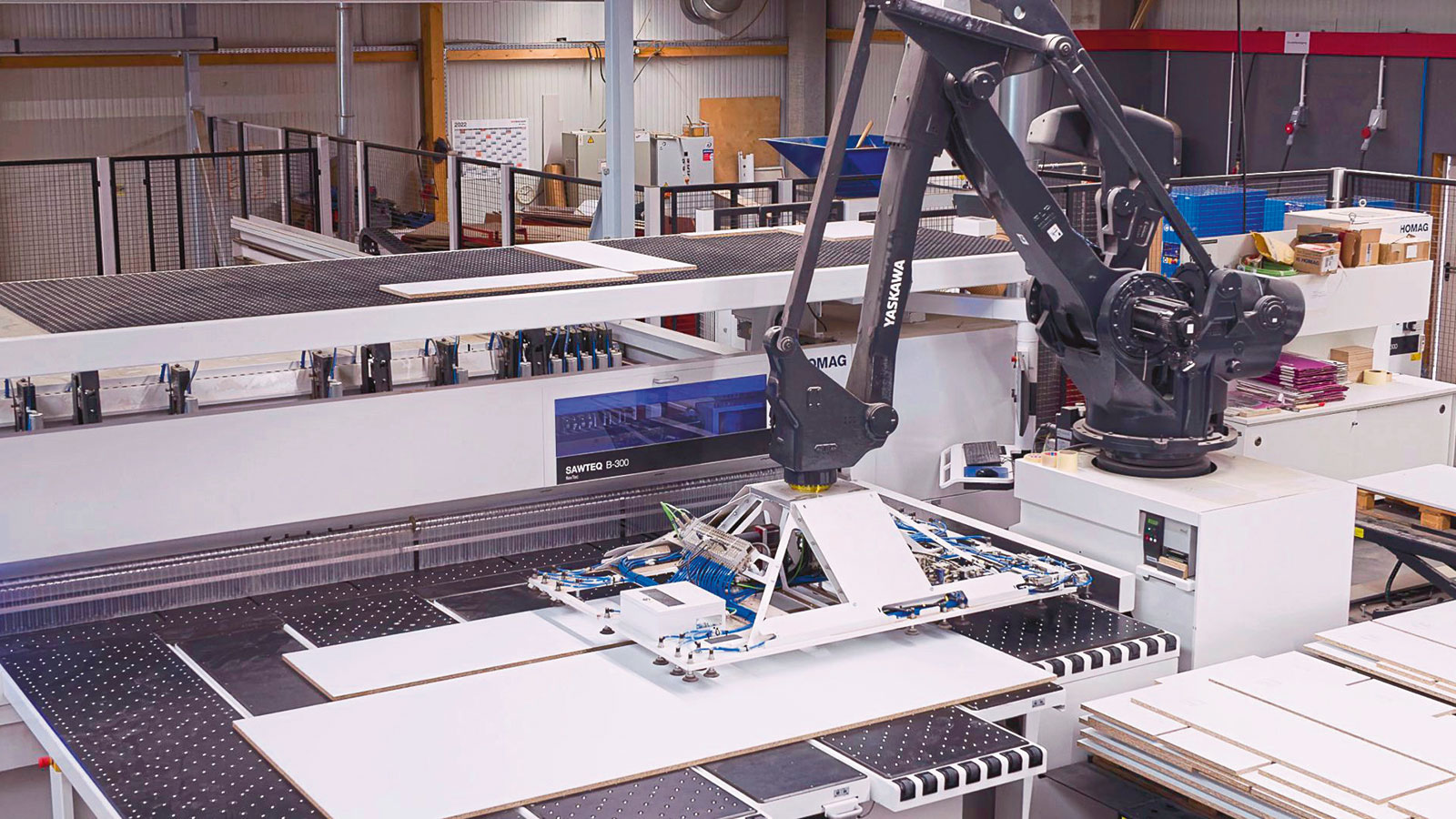

When people hear the name Schwäbisch Hall, they often think of the popular advertising slogan: "You can build on these stones." However, Schwäbisch Hall is also name of the city where Neue Räume GmbH is based — a company that, for some time now, has offered custom-made kitchens, enabling property owners to add value to their homes. A SAWTEQ S-300 flexTec (formerly SAWTEQ B-300 flexTec) from Homag supports the company with cutting tasks.

Eight years ago, Bastian Wahl and his company Neue Räume GmbH began producing high-quality, custom-made fitted kitchens. The entry into kitchen production was actually pure coincidence, since Wahl—a qualified industrial engineer and carpenter—was rather disappointed when conducting his own search for the right fitted kitchen. He was unable to find what he was looking for in any kitchen studio: an elegant, custom-made kitchen with a straight-line design, functional and finished to a high standard, all at a fair price.

This experience was the starting point, and from then on Bastian Wahl set his sights on revolutionizing the world of kitchens. Wahl believed that carpenter-made kitchens should be brought into the modern era with the help of the latest computer programs and high-tech wood processing machines, enabling on-time industrial production at the highest level while also maintaining the manufacturing concept. Today, the custom-made kitchens are offered under the label "NR Küchen."

Directly after entering the kitchen production sector, Wahl achieved astonishing growth. The majority of his machines are from the Homag Group, and he has been working successfully with the company for many years. Two years ago, due to the increasing demand, he decided to significantly expand his production: "Initially, we only wanted to build a hall of around 600 square meters, but ultimately decided on 900 square meters to ensure we had space for a SAWTEQ S-300 flexTec from Homag. This saw is exactly what we need to prevent any bottlenecks from arising and to enable us to achieve our growth targets in the medium- and long-term," says Wahl.

The saw features an integrated robot and is technically capable of fully automated batch size 1 production over longer distances. Alternatively, the saw can be operated manually as usual, making it very flexible to suit your requirements. The saw is equipped with the CADmatic machine control unit, which enables innovative touch operation and guides the operator using an assistance graphic. The Cut Rite optimization software is used for cutting.

A STORETEQ P-300 storage system is connected directly to the saw for logistical requirements during operation. With the storage system, the flow of material is optimized, stock is managed transparently and processing machines are used in an optimal way. The storage system is operated via the intelligent woodStore storage control system from Homag, which grows along with the entire storage portfolio and therefore takes advantage of the full storage potential on a sustainable and individual basis at all times. The defined panels are fed to the saw from the storage system via a cross rail.

To ensure perfect positioning for achieving his future goals, in the past two years Bastian Wahl has invested in a conversion with integrated showroom and the purchase of new machines in the lower seven-digit range. It took around nine months from the time the order was placed to commissioning the saw and the connected storage system.

Although the saw can cut panels of more than 4.0 meters, the panels at NR Küchen are usually 2.80 x 2.10 meters in size, with a thickness of 8 to 60 millimeters. On average, around 40 individual panels are currently cut per day, sometimes in batch size 1.

"But, of course, the saw can offer much more and is therefore the basis for our further objectives. Fully automatic operation also brings us the desired savings potential, because, after the introduction, we now only require half the amount of personnel for operation," says Wahl. "Of course, we first had to familiarize ourselves with the new saw and the options in order to get the most out of the machine for us as a company. Obviously this is only possible with trained specialist personnel. With a skilled workforce alone, the complex control system can only be operated to a limited extent. But the purely digital process—from the control system to the storage system and the saw—was important to us, because this is the only way to be prepared for the future," continues Bastian Wahl.

With such a complex technology, a kitchen manufacturer must be able to rely completely on its machine supplier, because there is no room for failures. "Homag have always been willing to listen to concerns, especially during the early days with the usual challenges. From our perspective, good service is almost more important than the price itself, which must not play the main role in such an comprehensive investment," Bastian Wahl concludes.

And the next purchase is already in the pipeline. A new EDGETEQ S-500 edge banding machine with a LOOPTEQ O-600 gantry return from HOMAG is set to be installed at the Schwäbisch Hall site as early as July/August. The new machine features automatic destacking and therefore enables optimized supply to the next station, the two CNC machines.

Neue Räume GmbH in Schwäbisch Hall is run as a family business, now in its fifth generation. The company has always been committed to providing top-class carpentry and, as the owner, Bastian Wahl wishes to continue this tradition. With the production of high-quality, sustainable and custom-made kitchens at fair prices, he has succeeded in establishing his company as a premium kitchen manufacturer. The kitchens are exclusively intended for end customers, mainly in southern Germany at present.

NR Küchen designs, produces and assembles with a total of 25 employees. The quality of the materials and the optimal processing of each piece of furniture guarantee a service life that is typically twice the length of many other kitchen manufacturers, particularly in the premium sector. On-site in the kitchen studio, customers can take a look at the production hall, which is directly connected to the showroom on the ground floor. Thanks to the modern software solutions, the customer can see the exact location and status of each drawer and front of their kitchen at any time during processing.

But why should customers buy their kitchen from NR Küchen? "Over the past few years, we have succeeded in being perceived as a brand not only in our region, but also in other parts of the country thanks to active online marketing, since many people obtain information via the Internet. Our entire approach is based on our good, personal relationship with our customers. This includes transparent planning and ongoing consultation with completely open and fair pricing. This is exactly what the market is all about," explains Bastian Wahl.

“Homag have always been willing to listen to concerns, especially during the early days with the usual challenges. From our perspective, good service is almost more important than the price itself, which must not play the main role in such an comprehensive investment.”Bastian Wahl, Managing Director of Neue Räume GmbH