SCHULER Consulting at LIGNA 2023

Discover our key topics at LIGNA 2023. We look forward to seeing you there!

The world's leading trade fair LIGNA opens its doors from 15-19 May and we will be there! Visit us in Hall 15 at Stand G31 and discover our solutions for your future.

Our focus topics for LIGNA 2023:

- Strategic production development: Produce optimally, build economically.

- Digital Value Stream Optimisation: Full transparency of value stream and intralogistics.

- Consulting in timber house construction: Taking the company to the next level.

Shaping the future

For over 65 years, we have been implementing projects in the timber and furniture industry worldwide. We use our know-how to shape the future with you. We want to put you in the best possible position. Because only those who recognise opportunities, define the right means and implement them consistently will be rewarded. We examine the existing, question the tried and tested, discover potential and break new ground. This is how the future works today!

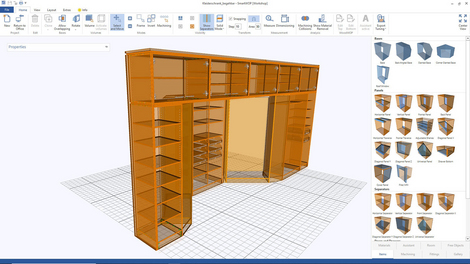

Whether it's a new building or a remodelling - we know our way around production planning!

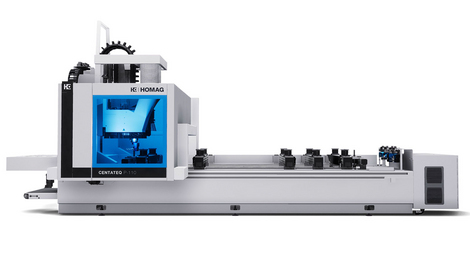

Whether a new building on a greenfield site, an expansion plan or a conversion - when it comes to planning the best production for you, we know our way around. We analyse what the optimal material flow in your production looks like, discuss the choice of technology, plan the positioning of machines and workstations and align production with your corporate goals. A holistic profitability analysis of the production concept and the technologies used round off the planning project. Your short- and long-term investment decisions are thus based on a well-founded overall concept that offers you planning security and enables a targeted approach.

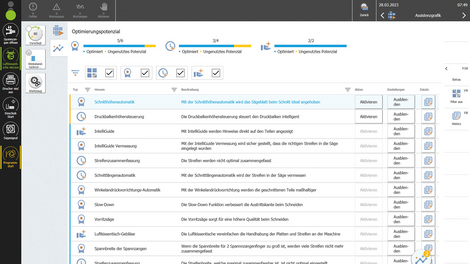

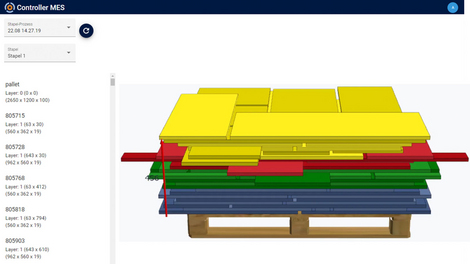

Digital Value Stream Optimisation: We make your value stream transparent

Consistent production data acquisition is often not possible in a heterogeneous machine park: different systems for data acquisition, machines from different manufacturers or from old years of construction cannot communicate with each other. The consequence? Influential factors such as process times or transport routes remain in the dark. The problem: what you can't measure, you can't optimise. This makes increasing the efficiency of production a challenge for manufacturing companies. Our solution brings light into the darkness: Digital Value Stream Optimisation by SCHULER Consulting makes material and goods flows visible by means of an indoor tracking system and records machine data through the use of external sensor technology, regardless of manufacturer and year of construction. All production data, including data from existing systems (e.g. ERP, MDA, MES), flow into a digital value stream dashboard. This data is the basis for the targeted and continuous optimisation of your value stream.

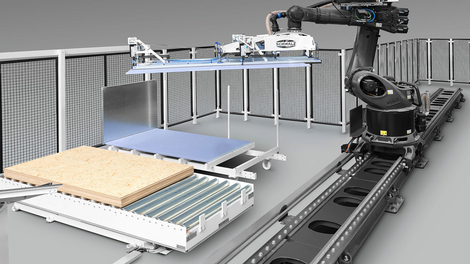

Well advised, better built. Aiming high with timber house construction!

Every company is unique, the challenges it faces diverse. Changes in the market leave no company untouched. If you want to keep up, you have to act. For timber construction, this means: streamlining and optimising processes, automating and digitalising. But where do you start? Where and how does the pulse of your company beat? Together with you, we evaluate how you can react to new market requirements and master future challenges.