tapio – Joint applications solve real customer problems

Four years is a long time, and tapio is all the more pleased this year to be able to show, live and in color, what has been realized in recent years. Starting with the visionary idea of building the ecosystem for the wood industry, tapio has achieved a great deal in recent years. Transferring machine data in real time via the Internet is now an ever-present feature, even though it was still science fiction when tapio was launched in 2017. tapio processes an average of 50 million transactions per day and significantly more at peak times. In addition to continuous growth with a steady doubling of licenses and expansion into new countries and languages (active customers in more than 35 countries, available in more than 10 languages), at the trade fair, for tapio, it is all about real use cases together with your business partners, to solve real customer problems together.

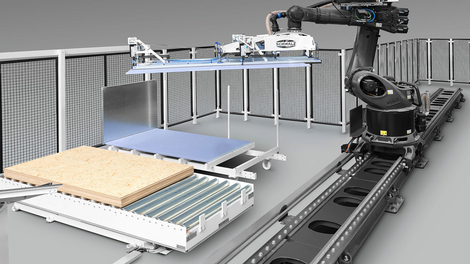

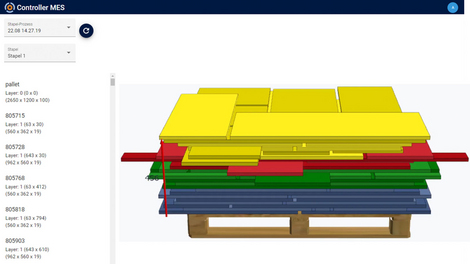

In 2023, tapio will once again be presenting itself at LIGNA as a strong partner for the digital networking of machines, tools, materials and customers in the timber industry. The special focus is on making the ecosystem tangible. In addition to machines, tools, materials and software providers play an increasingly present role in the tapio world. Thanks to the strong collaboration between the partners, it is now possible for the first time to exchange end-to-end data between all the important components really easily. The laborious manual work is coming to an end and scanning is becoming the new normal.

At the last LIGNA in 2019, tapio demonstrated "twinio" for the first time as an application for tools and materials. Since then, a lot has developed and 2023 now shows a real end-to-end closed circuit for the first time. Digital twins of tools and materials are brought to life and create direct added value for the machine operator and the company as a whole.

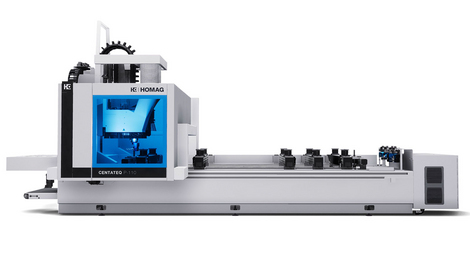

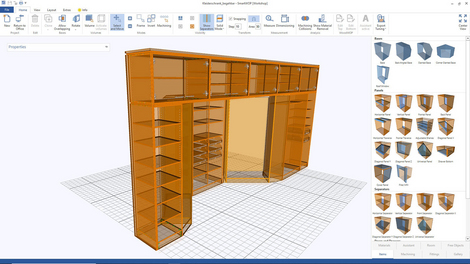

Linking individual solutions is still an important component in solving customer-focused problems in the joinery. In addition, together with the partners HOMAG, Leuco, AKE, Agefa, Kanefusa, Aigner, Rehau, Ostermann, Egger, SmartWOP, Borm, IMOS and iX, tapio will be presenting data-driven applications live on the HOMAG stand in a specially installed "woodworking shop cell." Two years ago, we deliberately asked what if the life cycle of a tool could be mapped digitally, if tool data were available directly on the machine and sharpening services could update current measurement data on behalf of the customer after the sharpening process with just one click (machine, tool and material could talk to each other). From May 15, 2023, you will receive an impressive response.

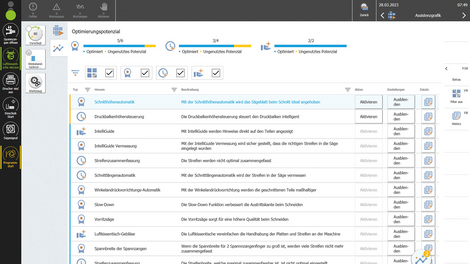

tapio will also present its initial product in a new look. With the new ServiceBoard as a web application, customers now have the option of creating and managing tickets directly on a PC or laptop. In addition to a new design (including dark and light mode), the video diagnostics have also been adapted to customers' requirements. Contact your service technician even more easily and quickly. And thanks to the automatic interaction between HOMAG serviceAssist and the tapio ServiceBoard, it is now even easier for users to save time and costs.