Sustainability at the trade fair: HOMAG CARES about sustainability

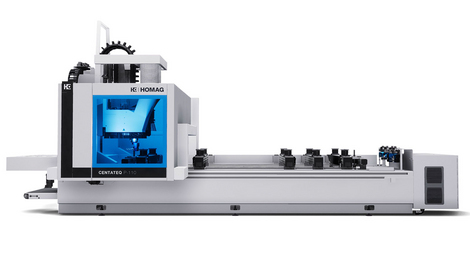

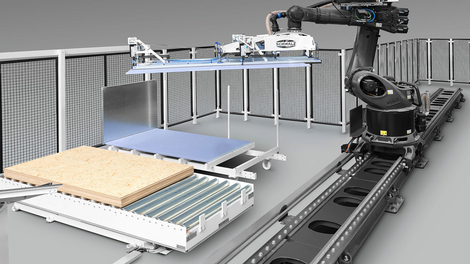

We have always taken care of the environment. We build efficient machines, rely on sustainable production processes, engage in social activities, use renewable energies and the raw material of the future: wood.

With HOMAG CARES, we are now bundling our measures under one roof in order to achieve our ambitious climate targets for a climate-neutral future as quickly as possible. Here, we set ourselves the goal of 2030 to reduce the ecological footprint and to allow even more sustainability to be incorporated into our production, but also into our customers' production. One of the first steps is LIGNA 2023 — our most sustainable trade fair appearance ever. The best thing about this is that even if we have saved tons of material, you don't have to miss out on a single milligram of trade fair experience.

Collect knowledge. Protect forests.

Would you like to know more about batch size 1, timber house construction or future strategies for joineries? Then our newsletter is just what you need. You select your interests and receive target group-specific information that will help you and your business to move forward.

Because digital newsletters also consume energy, as part of HOMAG CARES, we are making forests fit for the future. In addition to our basic support, we are donating €10 to local projects for each new newsletter subscription to support climate-resilient forest reconstruction.