WEINMANN Assembly Tables BUILDTEQ A-600

WEINMANN Assembly Tables BUILDTEQ A-600

The specialist tool for roof and floor production

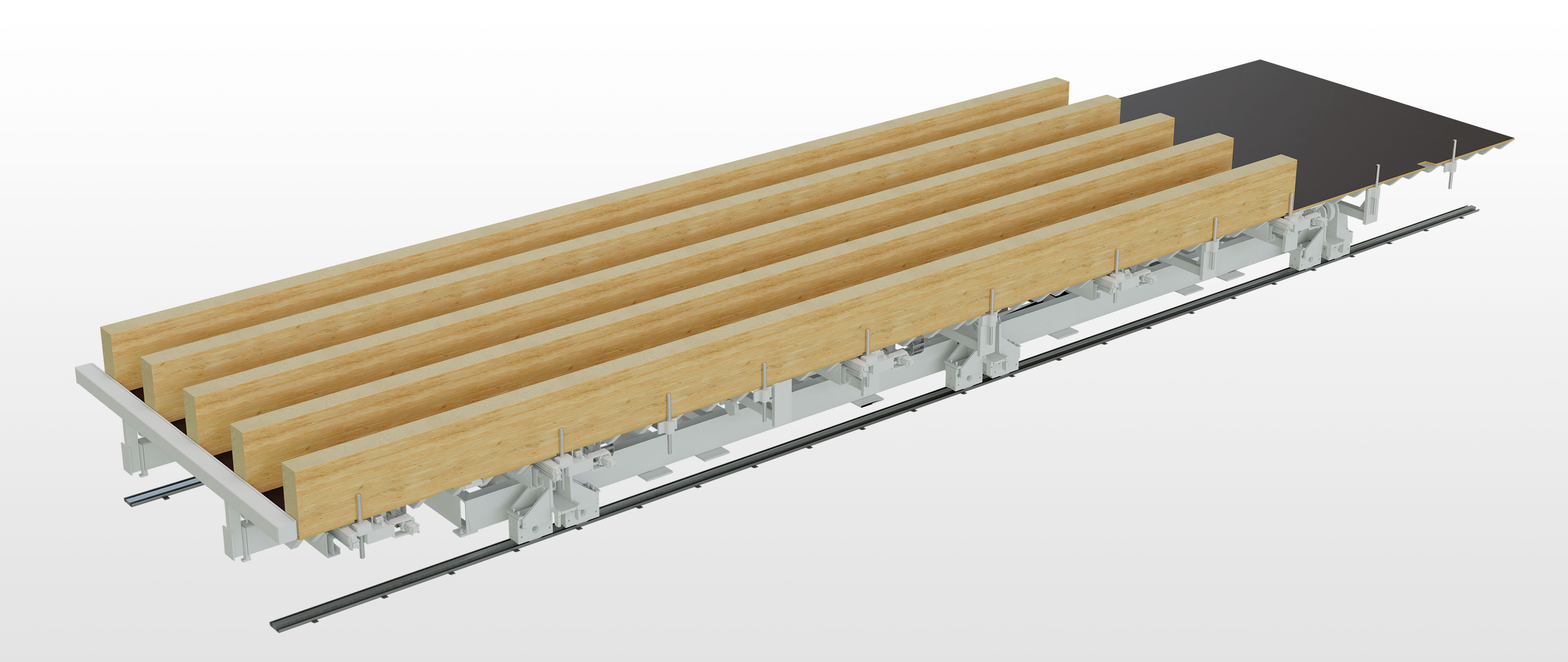

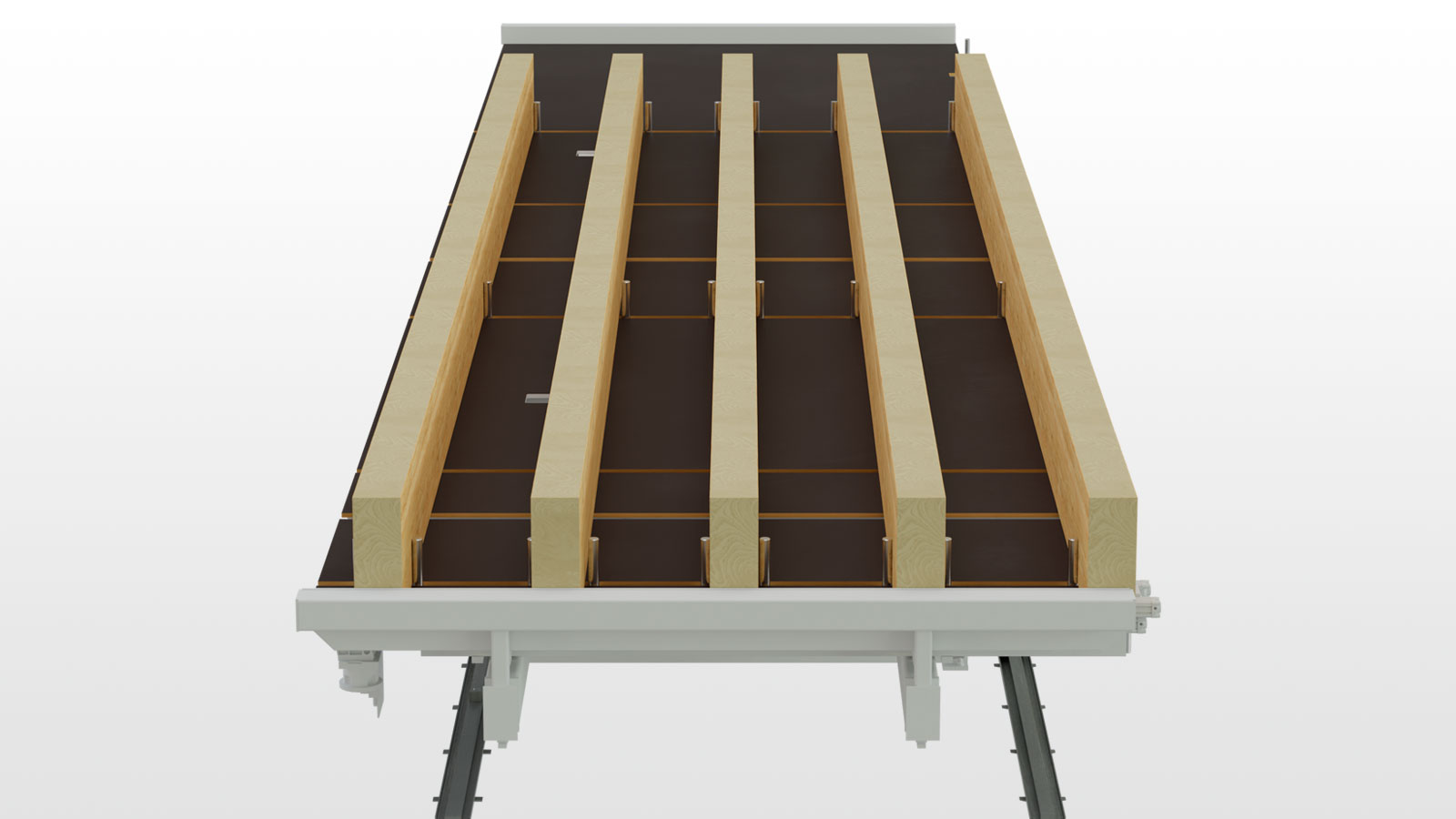

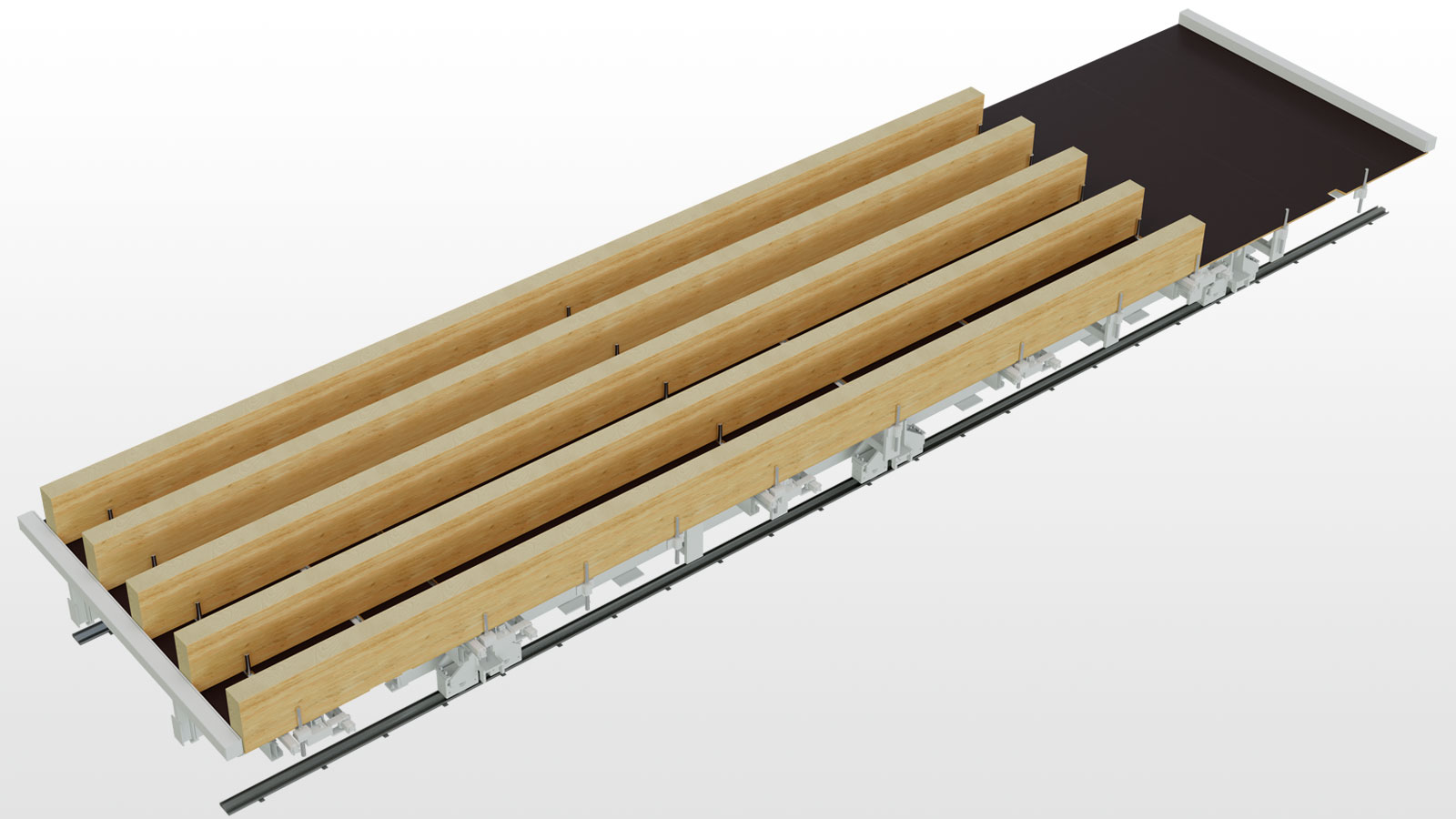

Produce your roof or floor elements quickly and easily with the BUILDTEQ A-600 . The table uses CAD data to specify the position of the beams fully automatically and clamps them securely. If the table is integrated into a production line, the elements can also be transported, installed and turned. The fully automated setup process is performed only during non-productive time, meaning that there is no waiting time from one item to the next. The table produces accurate rectangles and correctly mounted elements in next to no time.

Highlights

Automatic positioning: The NC-controlled clamping system enables fully automatic specification of beam positions based on the CAD data.

Time savings in production: Increased productivity thanks to fully automatic table setup during non-productive time.

Multi-station assignment: The roof and floor table enables simultaneous processing of multiple elements on a single assembly table.

Images

Features

-

Fully automated, CNC-controlled clamping units for clamping and aligning the rafter or beam layer

-

Longitudinal element transport for the transfer of elements to other workstations

-

Possible to use as a turning table with optional carriages

-

Automated turning function with a second table to protect materials

-

Production of rectangular elements with the X stop

Technical Data

| Element width [m] | 0.60 |

| Element width [m] | 2.6 (More features available as options) |

| Element length [m] | 2 |

| Element length [m] | 12 |

| Max. Element weight at 12 m length [t] | 3.5 |

All technical data are without engagement!

(Previous product name: Roof and floor table WTD 170 NC)

Here's how your colleagues produce

Brochures