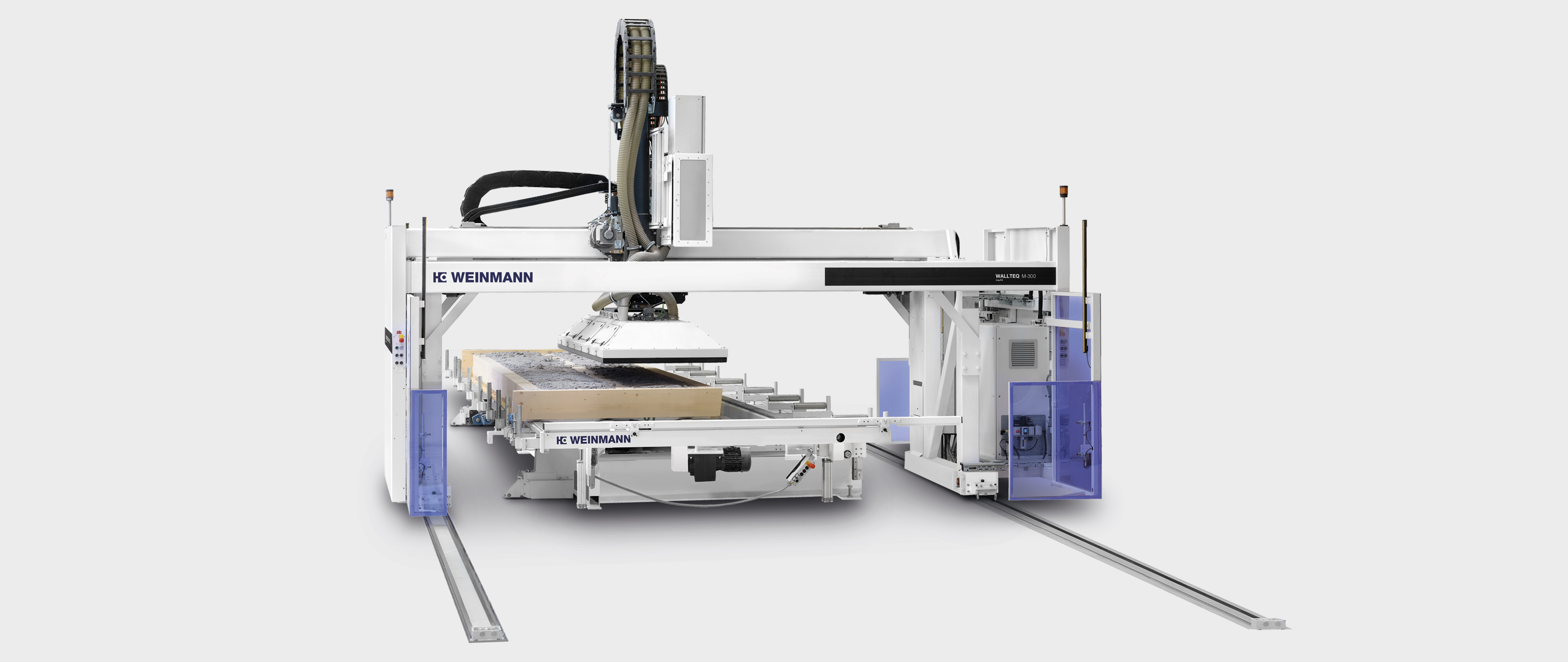

WEINMANN Multifunction Bridge WALLTEQ M-300/M-500 insuFill

WEINMANN Multifunction Bridge WALLTEQ M-300/M-500 insuFill

Your Solution for automated insulation.

With the WALLTEQ M-300 / M-500 insuFill, you can automatically insulate your timber construction elements such as external walls, roof and floor elements, gable triangles or special elements. The CNC-controlled multifunction bridge accurately moves the insulation plate over the respective frame work compartment. Through the digital interface, all data such as position, shape and size are stored in the CAD and then transferred to the insulation plate.

Highlights

Significant material savings as there is no waste and simplified storage.

Quality assurance due to complete documentation and optimal and consistent insulation density in each half-timbered construction thanks to the automatic determination of the fill quantity.

Increased workplace ergonomics thanks to the significantly reduced dust exposure and improved work processes for the employees.

Images

Features

-

Positioning of the blow-in plate with utmost precision above the respective frame work compartment

-

Automatic data transfer (position, shape, size) from all established CAD programs

-

Easy operation with the intuitive user interface powerTouch

-

Increased flexibility with regard to insulation material: cellulose, wood fiber, mineral wool and much more are possible

-

Simplified workflows and space savings through optimized logistics

-

There are 2 options available for different performance requirements:

- WALLTEQ M-300 insuFill: Integrated in production lines as a pure insulation station - ideal for small and medium-sized companies. Roof and ceiling elements can be automatically insulated with the optional rotatable insulation plate by 90 ° (available in both manual or pneumatic control).

- WALLTEQ M-500 insuFill: fully automatic insulation, fastening and machining in one machine. Ideal for use with medium-sized companies and industrial customers alike.

Various machining and fastening options are available, such as drilling, sawing, milling, marking, labeling, screwing, clipping and nailing.

Technical Data

| Max. element width [mm] | 3,200 optional: 4,200 |

| Max. element height [mm] | 500 |

| Max. element length [m] | customer specific up to 50, or greater lengths possible |

| Blow-in power [p / h] | approx. 1,000 (depending on insulation material and element) |

| Time required per wall element [min] 10 x 2,7 x 0,2 [m] (length x height x thickness) | 20 (depending on insulation material and element) |

All technical data are without engagement!

(Previous product name: Multifunction Bridge WMS 150 blowTEC)

Here's how your colleagues produce

Videos

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Vorfertigung mit der WALLTEQ M-300 insuFill

Einblicke in die Produktion bei der Terhalle Holzbau GmbH